The plastic Humanatones and Schwans were born too long ago to have gotten the benefit of a computer-improved design. Which were the first nose flutes designed, improved, tested, produced or even reproduced by new technologies?

2008/2009, then 2013/2014: The Bocarina®

Chris Schuermans is probably the first having had a nose flute printed. He designed the Bocarina® with 3D softwares, then used 3D printers to test different shapes.

First 3D print grown in a Stratasys Dimension machine using FDM (fused deposi1on modelling) from ABS filament:

|  |

|  |

« I experimented with clay Bocarinas and changed the design. »:

Experiments with the new design:

|  |

|  |

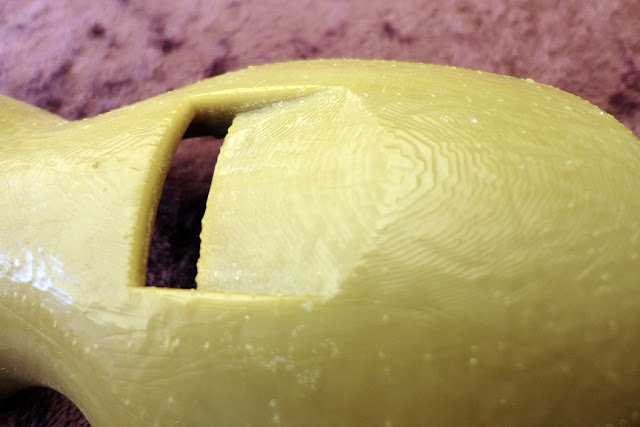

« After conducting some more experiments with clay I refined the fipple and finalised the design to make the final prototype in an EnvisionTEC technologies machine using SLA (selective laser acrylic) with photo-sensi1ve resin » (see below).

« The Bocarina mould was made using the CAD data of the 3D model used for this 3D print. ».

|  |

And as you can see in this post, a whole process began again some short years aftermath, with the Bocarina® Pro...

|  |

2010: The Pfaff Nasenpfeife

The patent for the Pfaff Nasenpfeife was filed in May 2010, and I assume this model was tested with 3D printing (in 2009?), but I do not have any evidence of it.

2012: Fuppi

Fuppi, the Japanese mass produced plastic hanabue, was born in 2014, but prototypes had already been made at the end of 2012 (see this post). The original model was the Adachi nose flute designed by master Kunio Katada, Fuppi's two parts mould and its inner design (with the purpose of being openable for cleaning) was, without any doubt, created on a computer. It's more than likely that first Fuppi prototypes were 3D printed (particularly in this hi-tech country).

2014-03: CRAI at ENSA Nancy

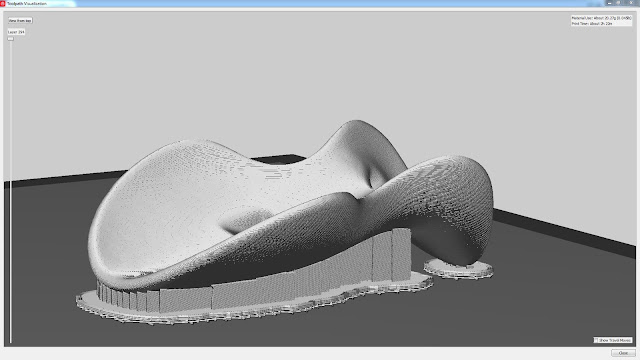

Here, we are not dealing with the design of a new nose flute, but with a joke/training/experiment lead by some of my former students. After their studies at Nancy (FR) National School of Architecture, some of them integrated the CRAI (our lab specialized in modelization). There, they had access to 3D scanners, 3D printers, etc. As a training with those hi-tech tools, they decided to copy a Bocarina® (sorry Chris... I wasn't aware of those funny pirates at the time...), in order to modelize it and be able to personalize it and make a surprise for me. I assume they wanted to recreate the external shield as a human face. Unfortunately, most of them left the lab before the achievement of this funny project. Anyway, Julien M., still there while completing his PhD., sent me the remaining files:

| |

|  |

|  |

| |

|  |

2015-03: Nose Flute by Mark Brocklebank

March 2015 is the first (known) date for a home designed and 3D printed nose flute. I found it on Thingiverse, the 3D printing open community. The Mark Brocklebank's nose flute is very simple, basic and coarsely printed, but it works! His creator even posted a video on his YT channel:

|  |

One interesting feature, on Thingiverse, is that what is published is offered to the community. So, anyone can download the files and make a home printed version of the object. That's what did two people, who also published a picture of their own "make"… Same file, but different printer and plastics:

|  |

2015-05/06: Nose Flutes by Maikel Mei

in May 2015, Maikel Mei sent me an email with pictures: « I have been working on the design of a 3D-printed nose flute. Today I collected the 3rd batch of the experiment, of which this is the most successful. It works, yet is far from perfect. It was printed in PLA. The proper version will be first printed in nylon in one piece. I am also thinking of liquid wood etc. The design is a combination of the W&L flute together with my own ideas and holds several innovations such as the extended chin shield and the reed holder. »

It's very interesting: Maikel Mei chose to print a 2 parts nose flute, longitudinally and symmetrically cut!:

The next month, Maikel had made a 3D printed copy of his silver Schwan-shaped Nasenflöte: « A new maker made a 3D-replica of my silver W&L. It contains a few tweaks that should make it a better instrument when printed in metal or ceramics. I will go for another few tweaks next week that will make it the best possible instrument. The print in the pictures was made in an hour from bronze ABS-string, just to have a result. Even without a proper labium it works nicely, better than the ones made by the first maker! »

Sadly, one side is not as clean as the other...

|  |  |

|  |

2015-11: Nose Whistle by Bob Taylor

Another nose flute appeared on Thingiverse last November. Bob Taylor designed and published this (more than) simple nose flute, but there is no picture of a 3D printed instrument, so we don't know if it was realized for real. Anyway, it would not have been able to whistle, having no air way!!!

--

Who's next ?

Great post Antoine! It is an honor that students at Nancy (FR) National School of Architecture chose to scan and copy the Bocarina!

ReplyDeleteThank you Chris! Well, I suppose it was a challenge for them, since the Boc has no plane surface to use as a growing base. I regret a bit they had not enough time to complete their idea, and make a Bocarina with eyes and nose :)

DeleteInteresting blog, this is the first time I heard about the Nose Flute instrument. Making this instrument using 3D printing technology is a great idea.

ReplyDelete